96 hour salt spray test|real life salt spray test : purchase • Corrosion• Corrosion engineering• Cyclic corrosion testing• Environmental chamber• Japanese Industrial Standards See more 16 de mar. de 2023 · ¿Cómo retirar dinero de Bet365? Para proceder a la retirada de fondos de la plataforma, Bet365 nos ofrece diversas opciones a modo de métodos de .

{plog:ftitle_list}

14 de ago. de 2018 · Passo a passo básico para abertura de um cofre mecânico. Encontre cofres mecânicos e digitais em nossa loja: http://cofresventura.com.br/Tambem no Mercado li.

The salt spray test (or salt fog test) is a standardized and popular corrosion test method, used to check corrosion resistance of materials and surface coatings. Usually, the materials to be tested are metallic (although stone, ceramics, and polymers may also be tested) and finished with a surface coating . See moreSalt spray testing is popular because it is relatively inexpensive, quick, well standardized, and reasonably repeatable. Although there may be a weak correlation between the duration in salt spray test and the expected life of a See moreChamber construction, testing procedure and testing parameters are standardized under national and international standards, such as ASTM B 117 . See more• Corrosion• Corrosion engineering• Cyclic corrosion testing• Environmental chamber• Japanese Industrial Standards See more

The apparatus for testing consists of a closed testing cabinet/chamber, where a salt water (5% NaCl) solution is atomized by means of spray nozzle(s) using pressurized air. This produces a corrosive environment of dense salt water fog (also referred to as a . See moreASTM G85 is the most popular global test standard covering modified salt spray tests. There are five such tests altogether, referred to in ASTM G85 as annexes A1 through to A5. See more

Typical coatings that can be evaluated with this method are:• Phosphated (pre-treated) surfaces (with subsequent paint/primer/lacquer/rust preventive) See more• ASTM G85 Modified Salt Spray Test standard• Deutsches Institut für Normung e.V. DIN 50021 . See more salt spray test is a comparison and r&d test rather than Qc test, so it is easy to compare your current product with the past product, or new process with older one. I used it in . How many microns is required for 96 hours salt spray test. Thanks. Rizwan Aslam trading - Riyadh ksa November 24, 2014. A. Hi Rizwan. Even 5 microns of zinc (ASTM B633 "Mild" service condition) will deliver 96 hours to white rust if the chromate conversion coating is done well. But selecting the zinc plating thickness based on salt spray hours .

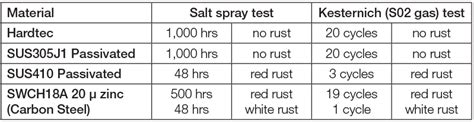

Comparison of 316, 304 and 430 type stainless steels in salt spray testing. Results from one testing laboratory, based on tests done to the ASTM B117 method suggest a 316 type part could be expected to pass a 96 hour test using a 3% salt spray. Indications are that longer test times would not be expected to give satisfactory results. ASTM B117 is a salt spray test used to provide information on the relative corrosion resistance of metal and coated metal samples exposed to standardized corrosive environments. is a very popular corrosion test and the .Additional Notes: Direct Comparison: Results from Salt Fog and Salt Spray tests should not be directly compared as they represent different aspects of corrosion resistance. Choice of Method: The choice between these methods depends on what you’re trying to achieve and the specific requirements of your industry. This table should provide a comprehensive overview of the . NASF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications - 10th Quarterly Report The NASF-AESF Foundation Research Board selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed .

The most common salt fog test durations are 72 hours, 96 hours, 240 hours and 600 hours. Keystone Compliance has expertise in completing salt fog testing per ASTM-B-117. With multiple salt fog chambers, including one that has an inside dimension of 8’ x 4’ x 4’. The primary test equipment required for salt-spray testing is a salt fog chamber.

salt water spray test

salt spray time test

The salt spray test basis is ASTM B117, 96 hours no white rust or red rust. The test was passed, but customer refused to accept the parts because they found 1 black spot on a sampled part. Now, he asks for a standard to testify that black spot is allowed after salt spray test is passed, before he can accept this lot. Nickel plating failing 96 hour salt spray test. A. Hi, Ahmed. We've appended your inquiry to a thread that may help answer it (see also letter 53155 "To Pass 24 hours of Neutral Salt Spray Test in Nickel and Chrome Plating").It strikes me that the fact that you are able to get 24 hours from your current process is good, and serves as evidence that your process is .

4 Back to TOC www.cwfinishing.net • 715.355.5789 • [email protected] Salt Spray Testing Cyclic Corrosion Testing Contents Standardization and Repeatability

The salt spray test takes advantage of a phenomenon known as "Oxygen Concentration Cell Corrosion."4 If a drop of water rests on a metal surface (Fig. 1) there is a difference in the volume of . For Salt Spray Test Exposure, hr 24-100 24-336* 24-96 24-336+ 500-2000 500-4000 6-24 96-1000 Simulated service condition Indoors: mild exposures . The suppliers plating vendor is supposedly an expert at plating powdered metal parts. After 96 hours of salt spray, we specify zinc and a yellow Trivalent conversion coating to ASTM B633 Type II. The samples came back from Salt Spray and were covered with white corrosion. I asked the lab that ran the tests what the pass/fail criteria was.exposure durations of 48, 96 and 168 hours. Upon chemical cleaning and drying the panels are weighted to 1/10000th of a gram (0,0001g). Annex X3 also contains repeatability and reproducibility statistics that can be used by laboratories as acceptance criteria for validating their salt spray testing cabinet.

The parts shall be capable of passing a 96 hour salt spray test to white corrosion and a minimum of a 200 hour salt spray test to red rust per ASTM B117. Typically, cadmium plus yellow chromate offered by PEM is .0002″ to minimum of cadmium applied to all significant surfaces. Significant surfaces exclude such features as threads, holes, deep . However, salt-spray tests do not always accurately predict how a protective coating may perform in the real world, as is the case with hot-dip galvanized steel. ASTM B117, Standard Practice for Operating Salt Spray (Fog) Apparatus, is probably the most popular standard used to salt-spray test coated steel. Is salt spray testing appropriate for powder coatings? Q. Is salt spray testing an effective, industry standard, means for process control for a powder coating system? . 240 hours of salt spray, something has gone .

Setting Sail – Test Conditions Now, let's talk about time and temperature. Every good sea adventure needs the right conditions, and this test is no different. Typically, the salt spray test runs for 24 to 96 hours, depending on your testing goals. Adjust the temperature to add that extra spice – around 35°C (95°F) should do the trick. II With colored chromate coatings 96 (hours) III With colorless chromate conversion coatings 12 (hours) IV With phosphate conversion coatings (hours) . If your supplier is doing the salt spray testing in-house, you can ask for it to be done (at your expense, of course) at an independent lab, and make acceptance contingent on the results of . The ASTM B117 salt spray test is an internationally recognized standardized test method, is employed for evaluating the. . Typically, the test duration ranges from 24 to 168 hours. However, longer durations may be required for more rigorous evaluations. Longer test durations provide more accurate representations of real-world corrosion .

Salt spray test is an accelerated anti-corrosion evaluation method for artificial atmosphere. It atomizes a certain concentration of saltwater; then sprays it in a closed constant temperature box, and reflects the corrosion resistance of the tested sample by observing the change of the tested sample after being placed in the box for a period of time. How many hours salt spray test is equivalent to years? There is no direct conversion between salt spray test hours and real-world years, as environmental conditions can vary significantly. However, 1000 hours in a salt spray test may roughly simulate a few years of outdoor exposure, but this can vary depending on the specific environment and .Continuous salt spray test exposure at 35C +/-2°C with a salt concentration of 5% NaCl +/-1%. Three variations within the standard give three options: • NSS – Neutral Salt Spray • AASS – Acetic Acid Salt Spray • CASS – Copper-accelerated Acetic acid Salt Spray (50°C +/-2°C). 1.3 The chamber will be loaded with test samples asASTM B117 Testing – Common Questions. 1. Why do I need to run an ASTM B117 test? ASTM B117 is a salt spray test used to produce relative corrosion resistance information for specimens of metals and coated metals exposed in a standardized corrosive environment. It is recognized internationally and widely used in the following industries: automotive, paints and coatings, .

Salt Spray Hours Electrical Conductivity Operating Temp. Range . SC 3 96 Conductive -65° to +200°C Glenair's standard high-durability electroless Nickel finish. MT Aluminum Nickel-PTFE AMS2454 500 Conductive -65° to +200°C Glenair's standard electroless Nickel-PTFE finish. NC Aluminum Zinc-Cobalt, Olive Drab ASTM B840, over electroless .

bient room temperature, for a minimum 72 hour duration, before any testing commences. 3 Testing 3.1 Salt spray test a) Apparatus – The apparatus used for salt spray testing shall be of such design as to conform to ASTM B117-03, “Standard Practice for Operating Salt Spray (Fog) Testing Appa-ratus.” b) Test performance – Salt spray .Salt spray testing can be performed at various salt concentrations, with 5% being the most commonly used. Variations include the addition of other corrosive chemicals. The addition of such chemicals as Acetic acid & copper chloride increase the rate of corrosion, producing results in a shorter period of time. Salt spray test. Some clarifications. One of the main things to take in consideration is that of the ASTM B117 “Standard Practice for Operating Salt Spray (Fog) Apparatus” specification. In fact, this is not to be considered as the only existing.Test durations typically range anywhere from 24 to 96 hours, though testing can extend for thousands of hours for critical applications. The most common salt spray test standard is ASTM B117, though testing per MIL-STD-810 is also extremely common. Testing per MIL-STD-810 differs from ASTM B117 in that the sample can exposed in cycles that .

salt spray time chart

white label Evaporation Residue Testing

The Dholakia family household have four generations living under one roof; together, they navigate the many ups and downs of their lives.

96 hour salt spray test|real life salt spray test